Ventless technology… They don’t all work the same and here’s the reasons why…

Taylor UK supplies two different types of ventless technology used in commercial catering equipment; TurboChef rapid cook ovens and Fast Chef Elite fryers. Both ventless technologies work perfectly fine in their own right but they operate in very different ways, here’s the principle of how they work and why…

TurboChef Sota

Rapid Cook Ovens – Catalytic Converters

Turbochef was a pioneer in the development of ventless rapid cooking technology, the unique method in which TurboChef ovens cook requires a unique method of controlling the emissions produced during the cooking process.

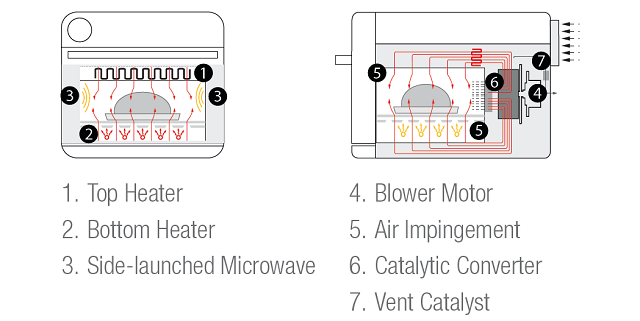

Rapid cook ovens are typically used for the fast heating, toasting and finishing of prepared menu items opposed to being used as the primary cooking platform. To heat, toast and brown products quickly, rapid cook ovens operate at a temperature around 260ºC which allows the product to colour quickly without drying out. The downside to operating at such high temperatures means that any grease and dirt that builds up in the cooking chamber will burn quite quickly releasing smoke and VCO’s (volatile organic compounds) which are the chemicals which you can smell and sometimes make your eyes water when items burn. The microwave element in rapid cook ovens only speeds this process up.

To prevent these VCO’s from being vented out into the working environment, TurboChef ovens don’t actively vent the cooking chamber, instead it re-circulates the hot cooking air through a heater and catalytic converter before it’s blown back into the cooking chamber, the process then repeats. The re-circulation helps reduce energy consumption and traps all of the smells and odours within the oven, they’re only vented to the working environment when the oven door is opened. The catalytic converter chemically ‘scrubs’ the air from the cooking chamber as it’s circulated through the system. The VCO’s are broken down by the catalyst compounds on the converter into inert compounds like C02 and H20. These inter compounds then naturally disperse when the oven door is opened. Turbochef ovens are continuously re-circulating the air through the system, which means the air is always being scrubbed even when the oven is idle between cooking cycles.

The catalyst system is ideal for rapid cook ovens as it is reliant on the high operating temperatures found in these types of oven. The hotter the oven is running, the more effective the catalyst functions. Unfortunately there is a limit to the effectiveness of the catalytic converter system, if you choose to cook raw fatty proteins, the excess grease which these products produce can overwhelm the system resulting in grease laden air, smoke and VCO’s being released into the working environment. In time, this excessive grease can clog up the converter rendering it useless.

To ensure that your rapid cook oven remains ventless, you must keep it clean. Preventing the unnecessary build-up of dirt within the oven will reduce the amount of VCO’s and smoke which the oven produces, taking the pressure off of the catalyst system

Find out about TurboChef Ovens here >>>

Fast Chef Elite+ Fryers – Condensation Filtration

The EcoFry system developed by Quality Fry for the Fast Chef Elite range of ventless fryers uses the condensation method to remove the grease, moisture and particulates create during the frying process. The catalytic converter method would not work in a ventless fryer, the temperatures are not sufficient enough to combust the VCO’s and grease would quickly clog up the catalyst.

The EcoFry system actively extracts the steam and excess grease produced during the frying process away from the frying chamber. This greasy, moist air is then passed through a condensation coil which causes the moisture to condense back into a liquid, trapping the grease molecules as it condenses. The liquid then runs into a catch tank which is easily emptied as required. The dry air is then passed through a metal particulate filter to ensure no large particles come into contact with the final stage – the activated carbon filter. The dried air is passed through activated carbon filter which passively reacts with the air, trapping any remaining grease molecules and odours before the clean, filtered air is vented back into the working environment.

The condensation process is simple and very effective. The system only requires cleaning once every 8,000 cook cycles where the activated carbon filter will also require replacing.

Find out about the Fast Chef Elite here >>>

Both ventless method allow the equipment to be located almost anywhere giving operators the ability to offer great hot food without the need of installing expensive extraction hoods.

If you would like some more information about either TurboChef rapid cook ovens or the Fast Chef Elite range of ventless fryers, call the Taylor UK Sales Office on 0800 838 896 or email sales@taylor-company.co.uk