Every piece of equipment used in the food service industry needs to be cleaned properly to maintain high food safety standards and to ensure that it keeps working in the correct manner, whether it’s a TurboChef rapid cook oven or a Taylor soft serve freezer.

Each equipment type needs to be cleaned in using the correct type of cleaner but do you know the difference between the different types of cleaner?

Taylor 152

Small gravity machine

Step 1 – Choose the correct type of machine cleaning chemical

There are three different times of chemical frequently used in food food service areas. Make sure you choose the right one for the job;

Detergents or De-greasers are required to clean items or areas which are greasy or oily. These materials do not kill bacteria.

Disinfectants should be used on surfaces which come into contact with food or hands, and must be of a ‘food safe’ type. They kill bacteria but do not have cleaning properties. It is important to clean items or areas with detergent before using disinfectants.

Stera Sheen Sanitiser

Sanitisers are chemicals which have detergent and disinfectant properties. When used in food preparation areas they must be of a ‘food safe’ variety. If you are using a sanitiser to clean and disinfect equipment which come into contact with raw and cooked process, a single stage clean is not suitable, and cannot guarantee the disinfection process. In the above situation a separate two stage clean then disinfect process must be carried out. You will need to clean the area as instructed by the manufacturer to remove any debris, then repeat the process to allow the disinfection process to be effective.

Taylor Recommendation

To clean and sanitise your Taylor soft serve or frozen beverage machine Taylor recommends using either Kay-5 or Stera Sheen sanitiser with milk stone removing properties.

What is Kay-5 or Stera Sheen Santiser?

These sanitisers have cleaning and sanitising properties designed to remove dairy residues from your machine whilst sanitising.

This powdered sanitiser comes in portioned sachets and is to be diluted at the rate of one sachet to 9 litres of lukewarm water.

Step 2 – Use it correctly

Chemicals must be used in accordance with manufacturers’ instructions. The three main instructions to check are;

• the dilution rate (if having to dilute the chemical from concentrate)

• the contact time

• the process required

The Dilution rate: this is normally listed in the instruction on the concentrated bottle or powder sachet, if not it may be on the data sheets. The dilution factor should not be guess work.

The Contact time: this is the time stated by the manufacturer on how long the chemical is required to be left on the surface in order to kill the required amounts of bacteria. This can normally vary between 30 seconds and 15 minutes. You should factor this time into account when purchasing your cleaning chemicals as to the practicality or leaving something for 15 minutes in order to effectively complete the cleaning process.

The Process required: The way in which a chemical must be used is specific to that product. You must ensure that you are following the manufacturers instructions for the process, some require a clean, rinse and wipe, some spray and wipe with damp cloth then dry, and some spray and dry. Check your cleaning instructions and ensure you and any staff are using it in accordance with the instructions.

How to Use Kay 5 or Stera Sanitising Powder?

Use either Kay-5 or Stera Sheen sanitising powders to clean your soft serve or frozen drinks machine. Make sure that you dilute it correctly – one sachet to nine litres of warm water. Use it as per the cleaning and disassembly instructions outlined in the operators manual specific to your machine. Ensure that you leave the sanitiser in the machine for at least five minutes to provide sufficient contact time for the sanitiser to work properly.

Step 3 – Choose your clothes and brushes carefully

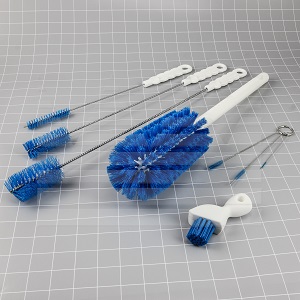

Taylor Cleaning Brushes

Disposable single-use cloths are recommended for cleaning surfaces and equipment. Where these are not used you must ensure that separate cloths are used for ‘dirty areas’ such as, where raw meat is prepared and ‘clean areas’ where ready to eat food is served and or handled. All cloths should be changed at least daily. If cloths are re- used they must be suitably cleaned after use. This will require a hot wash above 82°C. A wash cycle at 90°C will achieve this. Chemical cleaning in bleach is not considered suitable, this is because any organic matter, such as grease, dirt or food, left on the cloths can stop the disinfectant from working properly.

Taylor Recommendation –

Every Taylor machine is supplied with a suitable cleaning bucket and a set of brushes specifically designed to clean your machine. Each brush is of a suitable size to ensure that all areas of the machine are cleaned properly. Keep these brushes and bucket separate from any other cleaning products and only use them for cleaning your Taylor machine. Should you use cloths to clean your Taylor machine, these ideally should be of the ‘single use’ variety as it is imperative that the strictest hygiene standards are maintained.

Step 4 – Just do it!

A cleaning schedule can help initiate cleaning in areas that might otherwise be forgotten. Draw up a cleaning schedule for your business and stick to it!

Taylor Tip

If your not going to use your Taylor machine for a period of time after you’ve cleaned it (for example, laying it up for the winter) make sure you rinse any sanitiser from the machine with fresh, cool potable water. If sanitiser is allowed to dry on the stainless steel, it can sometimes cause discolouration or staining of the metal surfaces which can effect aesthetics and finish of the machine. Always ensure that a cleaned machine has completely dried before it gets put away.

If you would like to order some replacement cleaning brushes, additional sanitiser, a tune up kit or any other Taylor spare parts drop the Taylor UK Customer Service and Support Centre a line on 0845 601 2312 where one of our call centre operators will be happy to help.

2 Comments