Taylor UK’s ultimate commercial milkshake machine buying guide, full of advice and information to help you choose the perfect Taylor Milkshake Machine for your business…

What are we referring to when we say ‘milkshake’?

What types of milkshake are there?

Dairy based milkshakes are the traditional option and is currently the most common form being a variation on ice cream mix. But, like all successful products, the term ‘milkshakes’ has evolved to be accessible to fit in with the majority of dietary requirements and trends. Losing the ‘milk’ and shorting the term to simply ‘shakes’ opens up almost endless possibilities.

Currently you can get the following types of ‘Shake’ (there’s no doubt others):

-

Full fat, dairy milkshakes made using fresh milk, cream and stabilisers.

-

UHT ‘Thick Shake’ where a percentage of the fat is derived from a vegetable source.

-

UHT ‘Non-Dairy’ Shakes where all of the fats are derived from a vegetable source and there’s no milk-based ingredients. These products are usually vegetarian and Halal (check with the manufacturer).

-

Vegan shakes, where the fats are usually nut, coconut or soy based.

-

Fruit smoothies (not really a shake but…) made with a blend of fruits, sugar and water.

For the purposes of this article, we’re going to focus on traditional dairy based milkshake mixes and the Taylor machines which can be used to manufacture these products.

Milkshake mixes can come in different forms, each has the oven positives and negatives:

-

Freshly Prepared. This is a liquid that requires constant refrigeration until needed. It can be stored for 5 to 7 days before bacteria spoils it. Quality can be severely compromised by bacterial contamination and handlers must exercise caution to maintain quality. ‘Fresh mixes’ sometimes come deep frozen to extend shelf life; this then requires completely defrosting in a refrigerator prior to being poured into the soft serve machine.

-

A powdered mix. This is a dried version of the liquid mix. It has the advantage of easy distribution and can be stored for long periods of time without spoiling. Water or milk/cream must be added prior to being poured into the milkshake freezer. The disadvantage of a powdered mix is the ‘human element’ if staff members don’t follow the recipe correctly or the supply of ingredients is inconsistent, the finished product will be inconsistent. Some less honest operators can put too much water in to make it go further. Ideally the prepared liquid mix should be refrigerated prior to use, as airborne and waterborne bacteria can infect it immediately and can grow quickly if the product is warm. Residual bacteria in the refrigerated hopper could also be activated if a warm product is introduced.

-

Ultra-Heat-Treated (UHT) mix, is a liquid mix which has been sterilised and packed in sealed, sterile bags or cartons. It can usually last for up to nine months without refrigeration and can be poured directly into the milkshake machine immediately upon opening. At the time of opening, quality can be guaranteed, and bacterial counts are zero. Health authorities usually consider UHT the safest form of shake mix on the market. For best results, to assist with the efficiency of the freezer and for hygiene reasons, UHT mixes should also be pre-chilled before adding it to the milkshake machine.

When it comes to choosing the type of mix for your business you need to consider a few things:

-

Who am I selling it too? – Age group / those with religious beliefs etc.

-

How much can I sell it for? – Fresh mixes will always cost more to produce per portion than UHT equivalents. Make sure you have a mix which allows you to make enough margin on the product.

-

Will customers like it? – don’t make the mistake of trying to change the world too fast and too soon. If your customer base is used to a dairy based product, changing to a vegan product ‘over-night’ may lose you customers. Remember, just because you like it doesn’t mean the rest of the world will…

What’s the difference between commercial and homemade milkshakes?

Making your own ‘homemade’ mix for your milkshake machine will give you the potential to create a unique product which no other operator can sell. This allows you to source quality ingredients to generate a more premium product should you want, and you can avoid any ingredients which you class as ‘nasty’. The downside is that making your own will end up costing you more per portion, but you may be able to charge more if it’s a visibly more premium product.

View Our Range of Milkshake Machines

Things to think about when choosing your milkshake freezer…

Not all shake and frozen drink machines are created equal and making sure that you have the correct variation for your business will make all the difference. The initial purchase cost will always be a factor, but it shouldn’t be the main driving force when you make a final decision. You need to look at all the following points to make sure you have the correct machine for your business. Remember, the right machine in the right location could pay for itself within the first year!

But before anything else…

What is a commercial milkshake machine?

A commercial milkshake freezer is a standalone, self-contained machine which turns liquid base mix into finished frozen milkshakes on demand. Most machines are single flavour, usually vanilla. High-volume machines incorporate an on-board syrup system allowing the serving of up to four additional flavours of shake. Alternatively, a unique bag-in-box system, called Flavor Burst, can be installed on the majority of Taylor Frozen Drink Freezers, this allows you to serve up to eight additional flavours.

How do commercial milkshake machines makers work?

Milkshakes machines ultimately work in the same way as a soft serve freezer, the main difference being the point which the machine freezes the product to. Soft serve needs to be frozen solid, whereas milkshakes are frozen less to the perfect point where it’s thick and indulgent but still runny enough to be sucked through a straw!

Now you’re looking to buy a milkshake machine you need to ask yourself these two simple questions:

-

How many portions do you think you’ll sell a day?

-

At what point during the day do you think you’ll sell them?

If you’re looking to add milkshakes to your existing business and expect to sell shakes steadily throughout the day, but not in any large numbers all at the same time, then a compact, counter top, air cooled machine like the Taylor 430 will probably be able to cope quite happily with the volume demands of your business as this can produce 2 to 3 12oz shakes every minute without compromising the product quality. But, if you’re a convenience store of fast food or fast casual restaurant which has a busy spikes where you’ll need to serve a high volume of portions in a short time period then a much larger, pump fed machine like the Taylor PH61 would be better as this machine can serve 12oz shakes continuously through out the day without stopping!

For the best advice, and to find out what your potential annual profit and R.O.I. could be, contact the Taylor UK Sales Office to arrange free consultation with your local Sales Manager. Call 0800 838 896, email sales@taylor-company.co.uk or complete our Online Enquiry Form.

Once you have an idea on how many shakes you want to sell, and how quickly you need to serve them, you now need to choose which machine best fits your business…

Taylor Company manufacture several different machines which can be used to produce milkshakes (they can also be used to make a variety of other frozen drinks like cocktails, smoothies, fruit slushes etc.):

Taylor 430 – The 430 is a compact, air cooled machine which operates from a regular 13 amp power socket meaning this machine can be located almost anywhere within a business; in the kitchen, on a back counter in the serving area or by the till in a convenience store. The Taylor 430 produces 40 litres of finished shake every hour from a 3.8-litre freezing cylinder and holds 13.2 litres of liquid mix in the hopper. The cleaning cycle for dairy products is once every three days.

Taylor 428 – The 428 works in the same way as the Taylor 430 but has a much larger output capacity making it the better option for operators who are going to be serving a large number of servings in a short time period; business which are close to schools and want to capture some of the home time trade or restaurants which have busy spikes at specific times of days. The Taylor 428 produces 60 litres of finished shake every hour from a 6.6-litre freezing cylinder and holds 18.9 litres of liquid mix in the hopper. The cleaning cycle for dairy products is once every three days.

Taylor 432 – The 432 is a twin barrelled machine allowing the operator to serve two great flavours of the same product alternatively two different products; ideal for those operators who want to serve a vegan option along side the regular dairy shakes. The 432 requires a dedicated 16-amp power supply, is air cooled and counter top in design. The Taylor 432 produces 40 litres (in total – both sides combined) of finished shake every hour from two 3.8-litre freezing cylinders and each hopper holds 11.1 litres of liquid mix. The cleaning cycle for dairy products is once every three days.

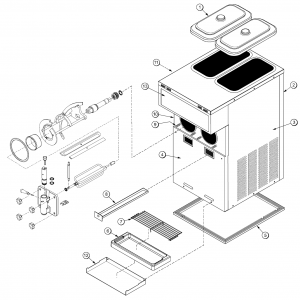

Taylor PH61 – This machine is for serious operators… The Taylor PH61 was designed for the 24-hour fast food industry. The machine features a heat-treatment system which means the unit is only switched off once every 14 days reducing downtime, maximising profits. It includes a built-in syrup system, the machine can serve up to additional flavours automatically at the push of a button and the ‘magic-eye’ automatically controls the dispense, stopping when the cup is full regardless of the size of it. The PH61 is a floor standing machine which requires a dedicated 32-amp three phase power supply and is available with either water or air cooling. The Taylor PH61 can produces shakes continuously throughout the day from a 6.6-litre freezing cylinder and holds 18.9 litres of liquid mix in the hopper. The cleaning cycle is once every fourteen days.

Taylor C606 – the ‘Rolls Royce’ of soft serve and milkshake machines! The Taylor C606 is the ultimate machine for fast food and fast casual dining. It’s a combination machine producing both soft ice cream and milkshakes all day, everyday… In simple terms, the C606 is a Taylor C708 soft serve freezer and a Taylor PH61 in one machine (it’s a bit more complicated than that) making it one step too far for most operators but if you’re in a busy location and serve a lot of ice cream and shakes then this is the machine for you!

Confused? Contact the Taylor UK Sales Office to arrange free consultation with your local Sales Manager to make sure you understand all of the options and get the right machine for your business. Call 0800 838 896, email sales@taylor-company.co.uk or complete our Online Enquiry Form.

How to make money selling milkshakes…

All food service equipment has inherent running costs associated with them; power, water, staff, product etc. and a milkshake machine is no different. The major difference is that a milkshake machine’s sole purpose is to create a unique product which customers cannot replicate at home. This means they have to buy it from you which in turn generates visible profit for your business. Not many pieces of catering equipment can boast that!

This is how profitable selling frozen milkshakes could be…

A typical profit example goes something like this:

R.R.P. 12oz Vanilla Shake – £1.95

Minus VAT at 20% – £0.33

Minus typical product costs (mix + cup) – £0.45

Average profit per shake – £1.18

Estimated shakes per day – 50 (six shakes an hour over an 8.5 hour day)

Potential profit per day – £59.00

Estimated selling days per year – 360 (Shakes aren’t a seasonal product like ice cream)

Potential Annual profit – £21,240.00!!

REMEMBER! If you sell your shakes as takeaway items, you don’t need to take off the VAT making them even more PROFITABLE!

The example above is quite conservative and would only warrant a small milkshake machine like the Taylor 430, which is the perfect add-on to any existing business as it’s a compact, counter top, air cooled machine which only requires a 13 amp plug socket to operate. In this circumstance, you could see a return on your initial investment in as little as 6 months!

You can create your own profit projection, using your own selling price and the number of portions which you think you’ll sell, by using our Profit Calculator!

Milkshake Recipes…

Taylor milkshake machines produce a perfect finished product straight from the machine, but you could add additional value to your offer by creating exciting recipes using the milkshake from your Taylor milkshake machine as the base…

Add a Flavor Burst – This isn’t really a recipe but… The Flavor Burst system is an add-on to any of the Taylor counter top machines allowing the production of eight additional flavours by simply pressing a button. The great this is you can create your own combinations by selection multiple syrups and the machine will automatically dispense those flavours in stripes straight in the cup; chocolate & mint or mocha & butter pecan…

Spin your shakes

Which businesses could sell milkshakes?

Fast Food Restaurants – Independent fast food operators can capture business from the major chains by replicating their product and making it better!

Fast Casual Dining – Milkshakes are becoming increasingly popular and installing a Taylor milkshake machine in a busy restaurant makes perfect sense; simply pour and serve – no measuring, no blending just quick and simple.

Convenience Stores – Capture some additional impulse sales when customers are at the checkout or maximise the spend from kids and their parents on the way home from school. It’s a great way of giving customers a reason to visit your shop!

Visitor Attractions – Complete you visitors’ day by providing concessions which they cannot make at home. The easy operation of Taylor milkshake machines means that even low skilled and seasonal staff can serve amazing shakes with the pull of a handle.

Cafes & Coffee Shops – Break away from the norm and offer your customers something different!

Maintenance & Cleaning

Commercial milkshake machines, like soft serve machines, require regular cleaning and routine maintenance.

Daily – all of the ‘touch points’ on the outside surfaces of the machine need to be cleaned and sanitised throughout the day to prevent any mix build up or bacterial growth. Heat treatment machines require the liquid mix in the hopper to be topped up regularly and require a few additional end of day procedures.

Every 3rd (or 14th day) – all milkshake machines will require a complete disassembly and brush clean either every third day (or on the fourteenth day if its a PH61 or C606 machine). The fully cleaned machine is then visually inspected, reassembled, lubricated and sanitised for use once more. Failure to strip and fully clean your soft serve machine in the correct interval may lead to machine failure or serious hygiene issues.

Quarterly – it’s recommended that all of the consumable components of your milkshake freezer are replaced once every 3 to 4 months. This includes scraper blades, nylon bushes and o-rings. Replacing these components helps to ensure that your milkshake machine continues to run efficiently.

Annually – It’s not obligatory but we’d recommend scheduling an annual Preventative Maintenance visit by one of our trained engineers on an annual basis. This service will check any key components ensuring that your machine is running as it should.

View the Taylor Operator Training Videos Here >>>

The Taylor UK Customer Service & Support Centre is open seven days a week, 364 days of the year to provide technical advice, arrange spare parts and consumables, or to organise a reactive service engineer visit as required. Call 01473 350047 or email service@taylor-company.co.uk

All Taylor soft serve machines come with a full on-site twelve months parts and labour warranty which, if it’s arranged within the first twelve-month period, can be extended up to four additional years. Contact the Taylor UK Customer Service & Support Centre for more details.

Hopefully this has provided you with a better understanding of milkshake machines and their applications, a complete list of Taylor commercial milkshake machines can be found here >>>