Want to sell frozen yogurt? Here’s our frozen yogurt machine buying guide…

Let’s make one thing clear, a frozen yogurt machine is the same as a regular soft serve machine!

There’s a few more considerations to consider if you’re planning on serving frozen yogurt opposed to regular soft ice cream. You can read the full Soft Serve Machine Buying Guide here >>>

Let’s begin…

What is Frozen Yogurt (sometimes called ‘Froyo’) and where did it come from?

Soft serve frozen yogurt, sometimes referred to as Tart Frozen Yogurt, is a ‘healthier’ alternative to regular soft ice cream. Typically, frozen yogurt products have little on no fat content giving the product a calorific value of around half that of ice cream. But it must be said, the remaining calories do come from sugar….

Frozen yogurt, as we know it today, was introduced to America by TCBY (The Country’s Best Yogurt) in the early 80’s. TCBY’s yogurt was a soft-serve product dispensed to order through a soft serve machine. TCBY became the largest frozen yogurt franchise in the world at that time. But demand for frozen yogurt slowed considerably in the late 90’s. Low-fat foods such as frozen yogurt fell out of favour as food trends favoured higher fat and lower cost ice cream at the turn of the millennium.

Frozen yogurt made it to the UK in the 1980 with the brand Colombo. The marketplace wasn’t quite ready for the product and consumers complained about the tart taste and preferred regular ice cream. In late-2000’s, following the rise in consumers love for all things yogurt. Early adopters launched brands like Pinkberry, Snog, Yoo Moo, Lick, Frae, amongst many others, in the UK and opened dedicated frozen yogurt shops with the sole aim of serving soft serve frozen yogurt to the masses!

How is frozen yogurt different to ice cream?

Frozen yogurt mixes usually have a ‘cleaner’ label in comparison to soft serve ice cream. The use of stabilisers and emulsifiers tend to be kept to a minimum and these are usually plant sourced products avoiding unnecessary animal sourced ingredients wherever possible.

What types of frozen yogurt are there?

FRESH MIX – Freshly prepared liquid that requires constant refrigeration until needed. It can be stored for 5 to 7 days before bacteria spoils it. Quality can be severely compromised by bacterial contamination and handlers must exercise caution to maintain quality. Fresh mixes are usually delivered to store deep frozen to extend shelf life; this then requires completely defrosting in a refrigerator prior to being poured into the soft serve machine. Pouring mix which hasn’t fully defrosted into a soft serve freezer can cause operational problems, so care needs to be taken.

POWDERED MIX – It has the advantage of easy distribution and can be stored for long periods of time without spoiling. Water, milk, yogurt, or a combination of all three must mixed with the powder to create a new ‘fresh’ liquid mix. If the operator used consistent ingredients and follows the simple recipe, a consistent quality product will be produced every time. Powdered mixes are a great starting point if you’re looking to add additional flavours to your frozen yogurt.

An example of a great quality, easy to use frozen yogurt power is Taylor UK’s Frozen Yopiu Powder, for more details click here>>

Ultra-Heat-Treated (UHT) mix, is a liquid mix which has been sterilised and packed in sealed, sterile bags or cartons. It can usually last for up to nine months without refrigeration and can be poured into the soft serve freezer immediately upon opening. UHT frozen yogurt mixes are difficult to produce by manufacturers and equally hard to source suppliers which can provide a regular supply.

What’s the difference between commercial and homemade frozen yogurt?

Just like regular soft serve ice cream, one of the unique selling points of soft serve frozen yogurt is the fact that you cannot recreate it a home. Soft serve is served at approximately -7ºC which makes it frozen, whilst being soft and easy to eat. It’s a product which is designed to be served and eaten straight away making it the definition of ‘fresh is best’.

Commercially available frozen yogurt sold in tubs is a very different product. It tends to be a firm, sometimes icy product which isn’t, as luxurious as its ice cream equivalents making it less desirable. Soft serve frozen yogurt is on a comparable level to ice cream.

What is a frozen yogurt machine?

A frozen yogurt machine is a regular soft serve freezer, the only difference being it’s calibrated to freeze frozen yogurt products opposed to ice cream ones.

Read our Ultimate Soft Serve Machine Buying Guide here >>>

Frozen yogurt mix usually contains little or no fat which effects the freezing characteristics in the soft serve machine. The day-to-day operation by the operator is the same, the only difference comes when one of the Taylor UK engineers visits the site to commission the machine. During this process, they will set the freezing consistency to the product being used. (It’s hugely import to make sure you have the correct mix ready when you receive your machine and to make sure you don’t keep changing mixes/suppliers as the freezing parameters may be different resulting in an inconsistent finished product).

View Our Range of Taylor Soft Serve Machines

Things to think about when choosing your frozen yogurt machine…

Say NO Heat Treat Machines – the ‘delicate’ nature of frozen yogurt products doesn’t allow them to work in a heat treatment machine. The mix can sometime split or curdle resulting in a watery, lumpy mix which won’t freeze properly. Also, if your frozen yogurt mix contains live cultures and pro-biotics, these will be destroyed by the heat process removing any of the benefits.

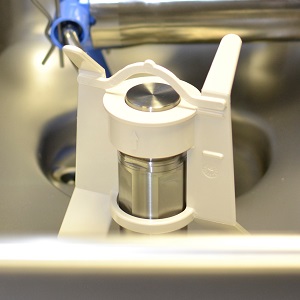

Say YES to Hopper Agitators –

How many flavours do you want to serve? – You choose a single machine like the Taylor C706 which serves one flavour of ice cream from one dispense handle. Alternatively, you could choose a twin machine like the Taylor C723 which has two independent mix hoppers and freezing cylinders allowing you to serve either two different flavours like natural and mango from the one unit. Twin flavour machines have a third handle which allows you to dispense both flavours at once in a spiral twist. If you want to serve more than two flavours, you will need multiple machines.

Pump or gravity? Gravity soft serve machines use gravity to transfer soft serve mix through feed tubes into the freezing cylinder whereas pump-fed machines use a pump to transfer the mix from the hopper to the freezing cylinder. Generally, pump fed machines are used for high volume applications which need a large volume of product in a short period of time. They also have the advantage of being able to regulate and increase the overrun, the amount of air whipped into the mix, which can increase the overall volume of the finished product and ultimately the profit you could make per portion. Gravity machines cannot adjust the product overrun and tend to be less expensive, easier to operate and clean making them more attractive to operators with limited skill staff. Only Taylor’s larger machines are available with pump options. Product quality should be a factor when choosing a pump or gravity machine. Not all products can take lots of overrun, frozen yogurt tends to max out at about 45-50% But remember, the higher the volume of air, the lower the quality of the product. Gravity machines tend to produce a product with 35-45% overrun.

Counter top or Floor Standing? – Taylor manufactures a wide range of soft serve machine machines ideal for frozen yogurt, the majority of which are available either as a counter top units which can be converted to floor standing with the use of a custom designed cart which can provide additional useful storage. This decision is usually driven by the available space and whether the machine is going to be used all year round as floor standing options have castors allowing them to be wheeled into storage if required. Larger twin flavoured machines like the Taylor C712 are only available as floor standing units. A major consideration when it comes to the location of your soft serve machine is airflow for cooling. Most machines tend to be air cooled which require suitable ventilation around the machine for it to operate correctly.

Confused? Contact the Taylor UK Sales Office to arrange free consultation with your local Sales Manager to make sure you understand all the options and get the right frozen yogurt machine for your business. Call 0800 838 896, email sales@taylor-company.co.uk or complete our Online Enquiry Form.

Which machine is perfect for your business?

A great add-on – The Taylor C152 is the perfect option for existing business looking to add frozen yogurt to their operation. The counter top design, air cooling and 13-amp power requirement means it can be installed almost anywhere. If you want to serve two great flavours, then the Taylor C161 is the option for you. It’s slightly wider than the C152 but gives you twice the options. Neither machine comes with hopper agitators, so intermittent manual stirring may be required.

A standout menu feature – If you want to make frozen yogurt an integral, key part of your business then having a larger, higher output machine might be the better option for you. Machines like the pump fed Taylor C706 is an ideal machine for those looking to serve one flavour. Whereas the Taylor C722 could be perfect for those with a desire to serve tow great flavours. Both machines are counter top with the option of them being fitted to a cart to make them floor standing. The C706 isn’t fitted with hopper agitators, whereas the C722 is fitted with them as standard.

Opening a ‘Froyo’ shop – A dedicated business needs a dedicated machine… The twin flavour Taylor C712 is the machine of choice for the frozen yogurt market. The floor standing design means that it doesn’t require and specialist counters to be fabricated – simply roll it into position! The pump-fed operation means it will always be able to keep up with demand and the hopper agitators mean you don’t have to worry about manually stirring the mix. Serve the same flavour from both barrels for maximum output, or give customers a choice of flavours… it’s entirely up to you.

This is how profitable selling frozen yogurt could be…

A typical frozen yogurt profit example goes something like this:

R.R.P. 5oz Frozen Yogurt Tub – £3.45

Minus VAT at 20% – £0.58

Minus typical product costs (mix + tub) – £0.65

Average profit per tub – £2.23

Estimated tubs per day – 50 (six tubs an hour over an 8.5 hour day)

Potential profit per day – £111.50

Estimated selling days per year – 280 (9 months)

Potential Annual profit – £31,220.00!!

Remember, this example is only based on nine months of trading, if you’re open all year your potential profit could be over £40,000.00!

The example above is quite conservative and would only warrant a small frozen yogurt machine like the Taylor C152, which is the perfect add-on to any existing business as it’s a compact, counter top, air cooled machine which only requires a 13 amp plug socket to operate. In this circumstance, you could see a return on your initial investment in as little as 6 months!

You can create your own profit projection, using your own selling price and the number of portions which you think you’ll sell, by using our Profit Calculator

Frozen Yogurt Recipe

Taylor UK supplies a powdered tart frozen yogurt mix called Frozen Yopiu. It’s manufactured for Taylor UK in Italy by Comprital Spa. It’s a great product as it provides a consistent base mix which has a long shelf life in powdered form, meaning you can limit wastage as you only need to mix up as much as you need when you need it.

Frozen Yopiu powder can be prepared in a number of different recipes, each giving a different finished product:

Frozen Yogurt Recipe A – Basic Smooth Product

-

1.5kg Bag Frozen Yopiu

-

6 litres Milk

Frozen Yogurt B – Richer ‘Creamier Tasting’ Product

-

1.5kg bag Frozen Yopiu

-

5 litres Milk

-

1 Kilo Natural Yogurt (runny, not set)

Frozen Yogurt C – Fresh Refreshing more Acidic Product

- 1.5kg bag Frozen Yopiu

-

3 Kilo Natural Yogurt (runny, not set)

-

3 Litres Cold Water

Mixing up your Yopiu frozen yogurt recipe:

-

Pour 6 litres of liquid into a suitably sized bucket or pail. The liquid could be milk, water, natural yogurt or a combination of all three depending on which recipe you’ve chosen.

-

Using a whisk, slowly sprinkle the contents of one bag into the liquid mixing continuously for a good minute or so to ensure that the powder begins to dissolve without sinking to the bottom.

-

Now the important bit – leave the mix to stand for 8 to 10 minutes. This allows the powder to re-hydrate fully and give the stabilisers time to start doing their ‘thing’. If you rush this the product won’t be right and you may end up with a slightly gritty/grainy product which is icy as the water in the mix hasn’t combined with the other ingredients properly.

-

After 10 minutes, give the liquid a good stir to ensure that everything has dissolved properly. Try to avoid aerating the liquid too much, excess foam will affect the freezing process and may cause other problems.

-

Pour the mix into your Taylor frozen yogurt freezer.

NOTE: The choice of milk depends on whether you want a fat-free or low-fat product. Use skimmed milk for fat free, or full fat milk for a creamier, more indulgent product.

Inclusions – Frozen yogurt is normally served in a tub instead of on a cone like regular soft ice cream. This allows the vendor to ‘add value’ by offering a wide range of toppings, sauces and inclusions which can be charged extra for. To keep with the ‘healthy’ vibe, fresh soft fruits are common, but sweets like gummy bears and cookies aren’t an uncommon sight in frozen yogurt shops. The ‘pick-n-mix’ toppings approach lets customers have exactly what they want, ensuring everyone leaves happy!

Typical Nutritional Information for Yopiu Frozen Yogurt – Recipe A

Recipe A – (6 litres SKIMMED Milk + 1.5Kg Frozen Yopiu powder)

Fats – 0.14%

Carbohydrates – 22.32%

Proteins – 3.14%

Fibre – 0.76%

Energy – 103.2 Kcal (431.6 KJ) per 100g

What are the alternatives to Frozen Yogurt?

Since frozen yogurt machines are regular soft serve freezers, they can be used for a wide range of different products. The only difference is how the machine is commissioned during installation. Other soft serve products include:

-

100% Dairy ice cream.

-

‘Dairy’ ice cream, where a percentage of the fat is derived from a vegetable source.

-

‘Non-Dairy’ ice cream, where all of the fat is derived from a vegetable source and contains no specific dairy products whatsoever.

-

Vegan soft serve, where the fats are usually nut, coconut or soy based.

-

Fruit based ‘sorbet’ style products.

-

Diabetic soft serve formulated using specialist sugars and stabilisers.

Maintenance & Cleaning

Frozen yogurt machines, like all soft serve machines, require regular cleaning and routine maintenance.

Daily – all of the ‘touch points’ on the outside surfaces of the machine need to be cleaned and sanitised throughout the day to prevent any mix build up or bacterial growth. Heat treatment machines require the liquid mix in the hopper to be topped up regularly and require a few additional end of day procedures.

Every 3rd day – all frozen yogurt machines will require a complete disassembly and brush clean either every third day. The fully cleaned machine is then visually inspected, reassembled, lubricated and sanitised for use once more. Failure to strip and fully clean your frozen yogurt machine in the correct interval may lead to machine failure or serious hygiene issues – remember you don’t want bad bacteria mingling with the good bacteria!

Quarterly – it’s recommended that all the consumable components of your frozen yogurt freezer are replaced once every 3 to 4 months. This includes scraper blades, nylon bushes and o-rings. Replacing these components helps to ensure that your froyo machine continues to run efficiently.

Annually – It’s not obligatory but we’d recommend scheduling an annual Preventative Maintenance visit by one of our trained engineers on an annual basis. This service will check any key components ensuring that your machine is running as it should.

View the Taylor Soft Serve Operator Training Videos Here >>>

The Taylor UK Customer Service & Support Centre is open seven days a week, 364 days of the year to provide technical advice, arrange spare parts and consumables, or to organise a reactive service engineer visit as required. Call 01473 350047 or email service@taylor-company.co.uk

All Taylor soft serve machines come with a full on-site twelve months parts and labour warranty which, if it’s arranged within the first twelve-month period, can be extended up to four additional years. Contact the Taylor UK Customer Service & Support Centre for more details.

Other Frequently asked questions…

Is Frozen Yogurt Healthy? – Fat free frozen yogurt is deemed by some to be a healthy alternative to regular ice cream due to the lack of fat. Typically, the calorific value of frozen yogurt is half that of regular ice cream, but the majority of those calories come from sugars.

How many calories in frozen yogurt? – Tart, natural or plain fat free frozen yogurt typically contains around 100 calories per 100g of product. Whereas conventional ice cream has closer to 200 calories per 100g. The calorific value varies between brands/manufacturers and flavours – fruit flavoured frozen yogurt will contain more natural sugars, therefore more calories!