Clean as you go…

The key to any successful food service business, but especially a dedicated Gelato or ice cream parlour is great hygiene standards and impeccable cleaning procedures. If your store looks grubby and unclean customers are more likely to go elsewhere!

Here’s our guide to the paperwork which you may need to run a successful and food safe gelato making business…

Food safety and hygiene is incredibly important and most aspects are easy to achieve with a little common sense and a bit of paperwork to keep a few records.

If you’re planning on starting a new gelato or ice cream making business from scratch, we recommend contacting your local Environmental Health Officer (EHO) sooner rather than later as they will be able to advise and guide you through the key points which you’ll need to fulfil before your business can open. The Food Standards Agency website is the best starting point for all the information you’re likely to need – www.food.gov.uk/business-guidance

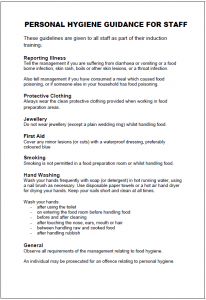

One of the first things they’ll probably mention is that all of your staff should have a basic food hygiene certificate, this is the minimum level of competency and managers should probably look to have either the intermediate or advanced qualification depending on the size and scale of your operation. Basic food hygiene certificates can be completed online these days. This link will take you to an example of a company which supplies these services – www.food-safety.org.uk (this is only a suggestion, we don’t endorse or recommend this site/company).

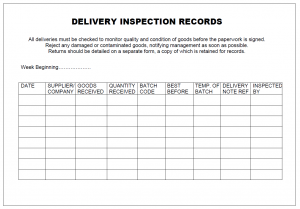

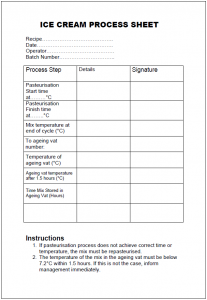

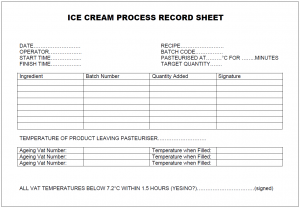

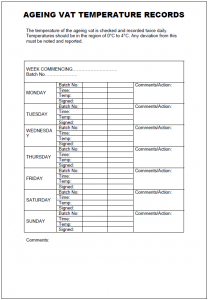

To compliment the information which your local EHO supplies you, below are some examples of additional documents which may help you to keep track of what you (and your staff) need to do to ensure that you’re doing everything possible to keep your gelato as safe and as amazing as possible.

Join us at one of our FREE Gelato Academy Open Days

We hold introductory open days at a locations in London, Manchester, Ipswich and Bodmin where you can come and see the whole gelato making process and learn how to make your very own.

Click Here to learn more about our Gelato Academy Days

Train Your Staff…

Train Your Staff…

Even if there’s just two of you, keep a record that everyone has been both inducted and trained on the operation and cleaning procedures for all of the pieces of equipment which you have in your business.

Update the record at regular intervals or when you employ new team members or introduce additional equipment to your business.

Keep copies of food hygiene certificates as well…

Request a FREE One-to-One Demonstration

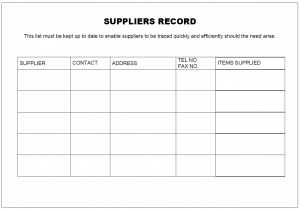

Know Your Suppliers…

We see it in the media sometimes where manufacturers recall ingredients or foodstuffs due to contamination of something. You need to know your supply chain so that you can act if some thing goes wrong!

Always remember the basic rule when it comes to stock control – ‘FIFO’ – First IN First OUT! If you get your team into this mind set straight away, it makes life so much easier down the line.

Make an Enquiry About Gelato Equipment Today

Keep a Production Diary…

You have a responsibility to know exactly which ingredients (and where they came from) went in to each and every batch of base mix and then the flavours which that mix then went on to make.

For example:

On Monday 15th July 2017 I made 30 litres of standard white base using these ingredients; 20 litres of milk, 2kg sugar, etc etc… The batch was pasteurised at 85°C and was chilled back down to 4ºC (+/-) well within 90 minutes. This is batch ’22’. This was held at 4°C (+/-) in the pasteuriser and was aged for 12 hours.

This process is especially important if you plan to distribute your gelato outside of your own establishment. Once you start supplying it to a third party, you have extra responsibility to make sure that its as food safe as possible!

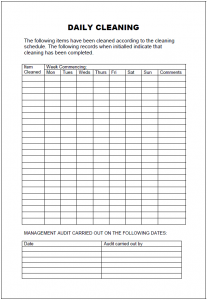

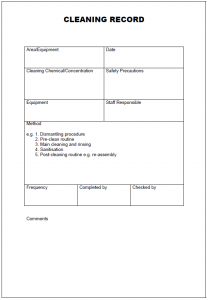

Keep EVERYTHING Clean…

Gelato and ice cream mix gets sticky and horrible quite quickly so make sure that you keep on top of the washing up at all times. Clean up any spillages immediately and mop floors regularly with a suitable floor cleaner/sanitser.

Common sense is the key!

Keep cleaning utensils and chemicals well away from food ingredients and production areas (especially those implements used to clean floors and toilet areas). The best thing to do is have clearly marked or colour coded buckets etc for the different jobs.

Never put components of your batch freezer or pasteuriser in the dishwasher. The excessive heat and chemicals can sometimes damage or distort precision parts causing them to fail prematurely. Dishwashers also have a habit of ‘eating’ small parts making them the easiest way to lose bits.

Keep a cleaning record. Whether that’s an hourly record showing that the customer toilets have been checked or a declaration stating that ‘Yes, I’ve sanitised my pasteuriser, batch freezer and utensils correctly before making a batch’. Keeping a record in your files is the best practice.

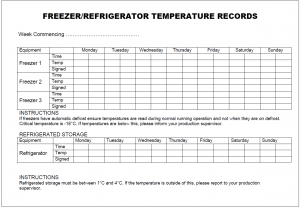

Keep Accurate Temperature Records…

Storage freezers need to be kept below -18°C (when storing Gelato, the colder the better…). Refrigerators need to be be below 7.2°C, typically refrigerators are set at +4°C, remember fridges don’t want to be set too cold as they’ll start to freeze things which is almost as bad as being too warm!

If you keep your mix in your pasteuriser or aging vat, you’ll need to keep a record that it’s been stored at a suitable temperature. Just like a regular refrigerator, this needs to be below 7.2ºC

Never trust the temperature read out on the display on the front of your fridge or freezer. Always use an external temperature probe to confirm that the piece of equipment is operating as it should. Temperature records should be taken at least twice a day; first thing in the morning and then again in the afternoon.

Make an Enquiry About Gelato Equipment Today

Request a FREE One-to-One Demonstration